Researchers from North Carolina State University have developed a groundbreaking process for creating cellulose gels, inspired by the nest-making process of small birds. This nontoxic freeze-thaw method offers a simple and cost-effective solution for producing cellulose gels that have a wide range of applications, including tunable gels for timed drug delivery. Through this innovative approach, the team was able to create cellulose gels from bamboo and potentially other plant fibers containing lignin.

The Challenge of Cellulose Hydrogel Creation

Cellulose is highly valued for its ability to create hydrogels, which are utilized in various fields such as contact lenses, wound care, and drug delivery systems. However, the process of creating hydrogels from cellulose has traditionally been complex and often involves the use of toxic solvents. These solvents are difficult to handle and can lead to instability in the resulting gels. As a result, researchers have been seeking a more efficient and safer method for producing cellulose gels.

The researchers at North Carolina State University found inspiration from a particular family of small birds known for their nest-building abilities. These birds use their saliva as a natural resin to hold twigs together, forming a cohesive nest structure. Observing this phenomenon, the researchers wondered whether they could mimic the birds’ saliva to encourage cellulose fibers to interconnect or crosslink in the gel formation process.

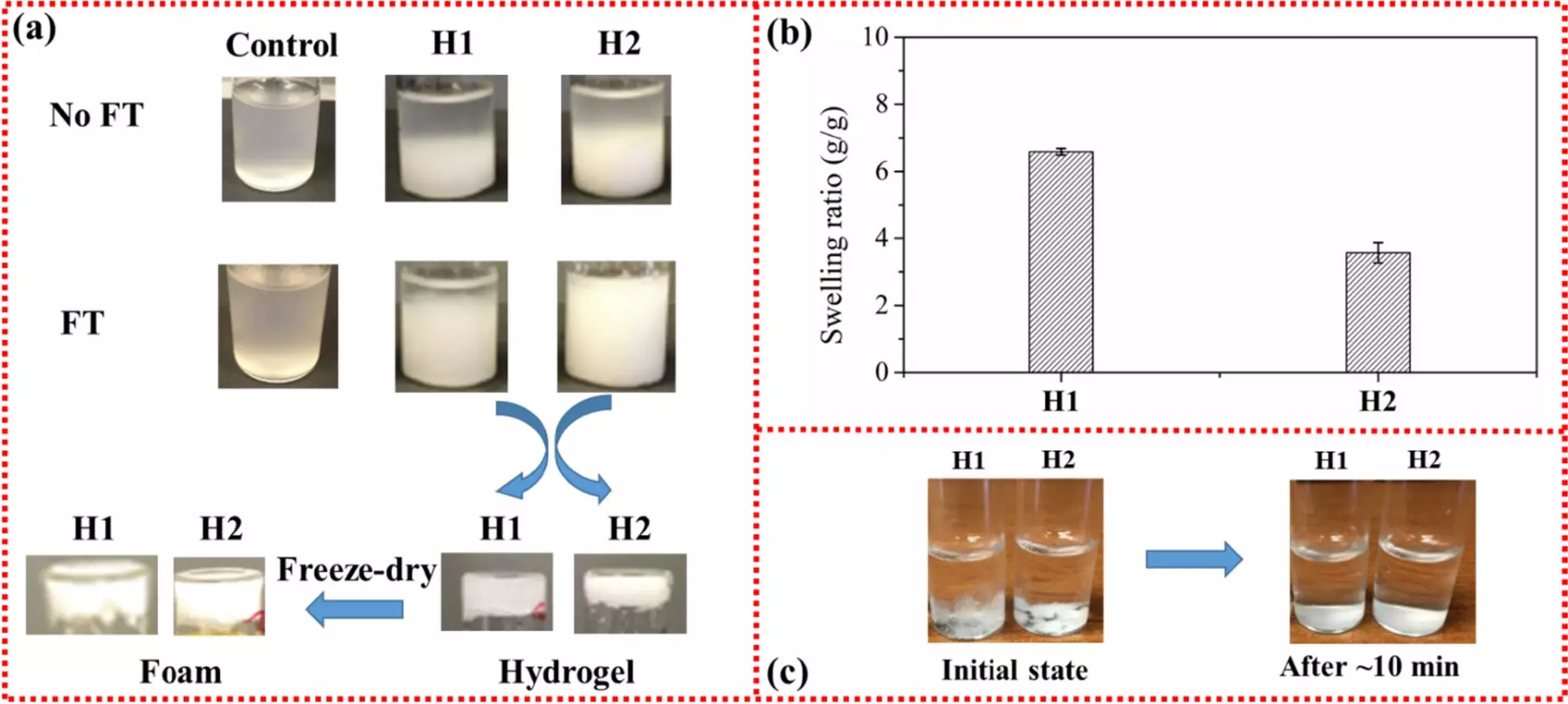

To emulate the birds’ saliva and create cellulose gels, the researchers added carboxymethyl cellulose (CMC), a water-soluble cellulose, to an acid solution. They then dissolved the CMC and introduced powdered cellulose fiber into the solution. The mixture was subjected to four cycles of freezing and thawing. This freeze-thaw process resulted in the formation of cellulose gel.

The freeze-thaw process delivers several advantages over conventional methods of cellulose gel creation. Firstly, it eliminates the need for toxic solvents that are commonly used in traditional techniques. By harnessing the properties of water and the pH change induced by the CMC, the cellulose fibers are able to compact and interweave, forming a more organized and stable gel network.

The research team also tested the effectiveness of the freeze-thaw process with bamboo fibers, which contain lignin and cellulose. Their success suggests that this method could be applied to other lignin and cellulose-containing plant fibers, expanding the potential applications of cellulose gels even further.

The cellulose gels created through this innovative freeze-thaw process exhibit remarkable resilience and stability at room temperature. Moreover, these gels can be customized to degrade on a predetermined schedule, making them highly suitable for applications such as timed drug delivery systems. Additionally, their robust nature suggests they could find utility in other areas of research and development.

The adoption of the freeze-thaw process for creating cellulose gels demonstrates a novel and sustainable approach to material science. By drawing inspiration from small birds and their nest-making process, researchers have successfully developed a non-toxic and cost-effective means of producing cellulose gels. This breakthrough in cellulose gel production has the potential to revolutionize fields such as drug delivery, wound care, and beyond, providing safer and more efficient solutions for various applications.

Leave a Reply