Polymer recycling is an essential process in the development of polymeric materials. It plays a significant role in reducing carbon emissions associated with materials production. However, recycling plastics and plastic-like materials is not a straightforward task. It requires the ability to effectively dissolve these materials using organic solvents. To overcome the limitations of experimental data, scientists at Mitsubishi Chemical Group (MCG) have developed a novel machine learning system for determining the miscibility of polymers with different solvents. This breakthrough has the potential to revolutionize the recycling industry by enabling efficient and selective separation of plastics.

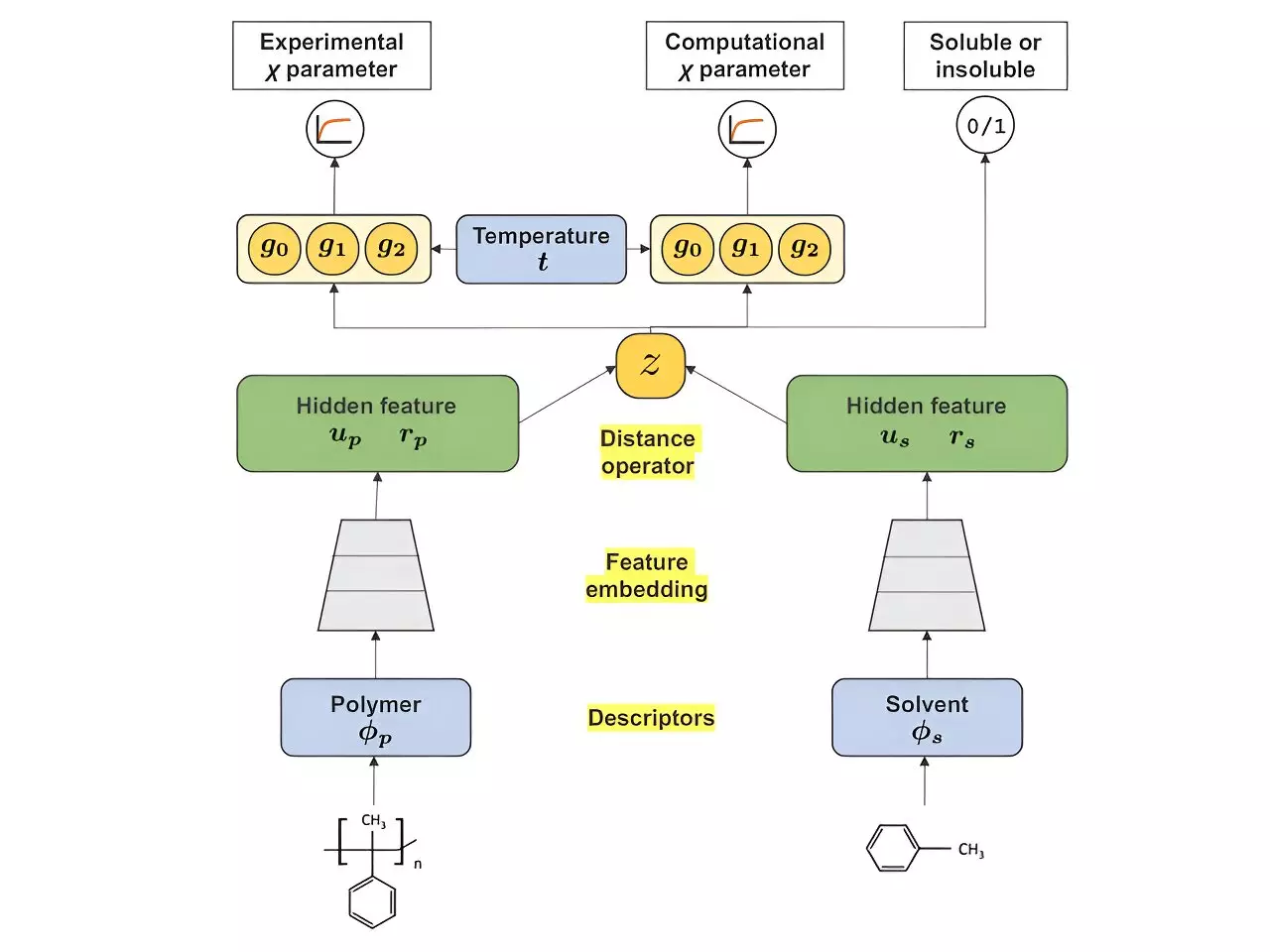

Polymer-solvent miscibility is a crucial factor in the recycling process. The ability to predict and understand the compatibility between polymers and solvents allows for the effective separation of different types of plastics and the creation of high-performance polymer blends. Traditionally, determining the miscibility required extensive experimental data. However, with the development of the machine learning system at MCG, researchers can now integrate data from both real experiments and quantum chemistry calculations. This approach, known as multitask learning, enables the construction of a highly accurate predictive model for miscibility.

Advancements in Quantum Chemistry Calculations

The machine learning system developed by MCG utilizes quantum chemistry calculations to compute the χ (chi) parameters, which are essential in determining the miscibility of polymer-solvent mixtures. This model has proven to be 40 times faster than conventional quantum chemistry calculations. By leveraging this rapid computational power, researchers can screen millions of candidate solvent molecules at an ultrahigh speed. This significantly reduces the time and resources required for selecting suitable solvents for recycling plastics.

The development of miscibilizers for various types of polymers holds immense potential in improving the recycling rates of waste plastics. As we move towards realizing decarbonized societies, technological innovations in recycling waste plastic resources play a crucial role. The predictive model developed by MCG provides a valuable tool for selecting and designing solvent molecules that can selectively separate certain materials in plastic waste. These designed solvents, known as miscibilizers, can also be utilized in the creation of high-performance polymer blends.

While the machine learning model developed by MCG has demonstrated impressive accuracy, there is still room for improvement. Currently, the model does not account for the dependence of a polymer’s miscibility on its molecular weight or other compositional features. To address this limitation and further enhance the model’s capabilities, MCG has made a portion of the developed source code and data available to the public. This open innovation approach allows for crowd-sourcing data, enabling the model to learn from a broader range of information and improve its representation of polymer miscibility.

Opening the data and source code to the public presents an opportunity to gather a vast amount of data in a relatively short period of time. The collective efforts of industry experts and researchers can contribute to the improvement and extension of machine learning techniques in the field of materials informatics. This collaborative approach promotes open science and accelerates advancements in the development of intelligent recycling solutions.

The Future of Polymer Recycling

The ability to predict and understand polymer-solvent miscibility through machine learning has the potential to revolutionize the recycling industry. As our society moves away from plastic-based materials, it becomes increasingly crucial to intelligently recycle waste plastics. By streamlining the recycling process and eliminating guesswork and trial and error, this technology can contribute to the development of sustainable materials and reduce our environmental impact. As Mitsubishi Chemical Group continues to innovate and refine their machine learning system, the future of polymer recycling looks promising.

Leave a Reply