The concept of developing artificial intelligence (AI) in computers was initially inspired by the intricate workings of biological systems. However, the current implementation of “neuromorphic” networks on computer hardware that bears no resemblance to the human brain severely limits their performance. To overcome this obstacle, researchers from Osaka University and Hokkaido University have embarked on a groundbreaking mission to create neuromorphic “wetware.” Their innovative work, recently published in the journal Advanced Functional Materials, could potentially bridge the gap between AI and the human mind.

Unleashing the Power of Memristive Devices

While neural-network models have achieved significant milestones in various applications, such as image generation and cancer diagnosis, they still fall behind the immense processing capabilities of the human brain. This discrepancy is largely due to their implementation in software using traditional computer hardware that fails to optimize the millions of parameters and connections required by these models. To address this issue, the researchers propose the use of neuromorphic wetware based on memristive devices.

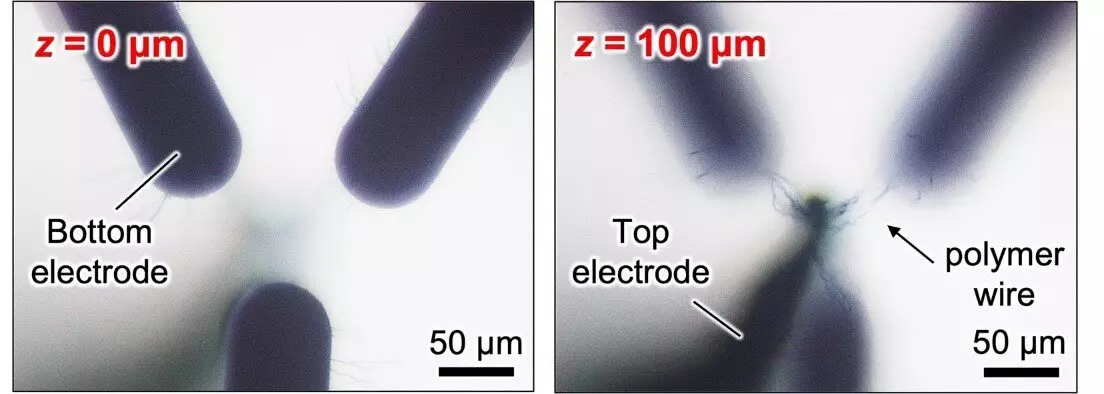

A memristive device is a unique device whose resistance is determined by its historical exposure to voltage and current. The team utilizes electropolymerization to establish connections between electrodes immersed in a precursor solution, employing conductive polymer wires. The resistance of each wire can then be fine-tuned using small voltage pulses, resulting in the creation of a memristive device.

Building a Three-Dimensional Network

Senior author Megumi Akai-Kasaya explains, “The potential to create fast and energy-efficient networks has been demonstrated using 1D or 2D structures. Our aim was to extend this approach to the construction of a 3D network.” To achieve this goal, the researchers successfully grew polymer wires from a widely used polymer mixture called “PEDOT:PSS.” This mixture possesses exceptional properties such as high conductivity, transparency, flexibility, and stability.

The process began by immersing a 3D structure composed of top and bottom electrodes in a precursor solution. By applying a square-wave voltage to these electrodes, mimicking the formation of synaptic connections in an immature brain, the team was able to grow PEDOT:PSS wires between selected electrodes. Once the wires were formed, the researchers utilized small voltage pulses on one electrode to precisely control the conductance, thereby altering the electrical properties of the film surrounding the wires.

Lead author Naruki Hagiwara explains, “The process is continuous and reversible, and this characteristic is what enables the network to be trained, just like software-based neural networks.” The team successfully demonstrated unsupervised Hebbian learning, a process where synapses that frequently fire together strengthen their connection over time. Moreover, by manipulating the diameter and conductivity of the wires, the researchers showcased spike-based learning, a technique that closely emulates the processes of biological neural networks.

Looking Ahead

This groundbreaking research marks a significant milestone in the quest for neuromorphic wetware. The researchers plan to further enhance their work by fabricating a chip with a larger number of electrodes and utilizing microfluidic channels to supply the precursor solution to each electrode. These advancements aim to construct a larger and more powerful network, ultimately closing the cognitive gap between humans and computers. The path to neuromorphic wetware holds tremendous promise in revolutionizing the field of AI and unlocking the true potential of artificial intelligence.

Leave a Reply